Showroom

CNC gear hobbing machine can be employed for carrying out gear cutting, splines cutting and sprockets cutting processes. This milling machine integrates a hob, cutting tool that creates a series of cuts on the workpiece.

The broach, toothed tool in the broaching machine moves either horizontally or vertically, based on the machine used. Our company can supply both, horizontal and vertical broaching machines, for precision machining. The size of the workpiece to be machined can be small to medium.

Accuracy in gear hobbing process can be achieved when using gear hobbing machine. A number of parts in different quantity can be processed using this machine. It comprises a cutting tool called hob for cutting the teeth into the workpiece.

CNC gear shaving machine can be accommodated to perform finishing operation of gears. The operations that can be carried out using the machine are crowning and tapering. The cutting methods can be plunge, plunge with oscillation and conventional.

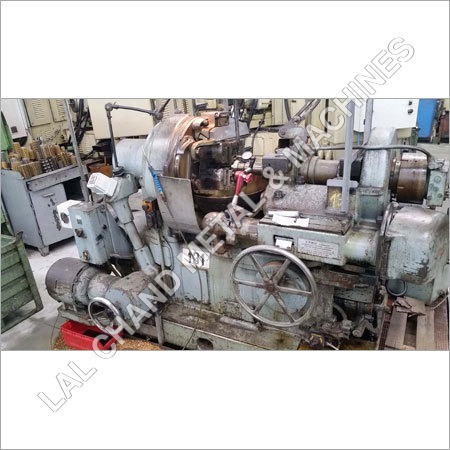

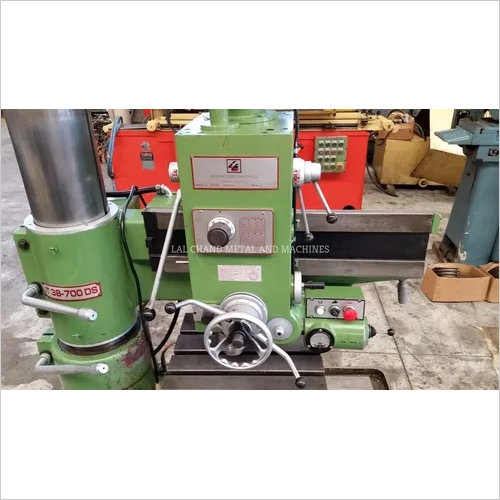

Get in touch with us to buy CNC floor boring machine for your workshop. This machine can be used for enlarging a drilled hole. We guarantee that this machine can achieve accuracy of the diameter.

The vertical machining center is composed of spindle, milling cutter, table, base, knee, Y-axis slide and top slide or overarm. Plunge cutting and drilling can be performed using this machine in medium to large machine shops.

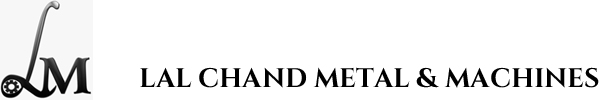

The operator of the tool and cutter grinder must be trained in order to efficiently grind and sharpen the tools edges. It can be used as cylindrical grinder and surface grinder, by using the apt fixture. The machine can be set based on the kind of tool to be used.

TRAUB A 25, DE BERNARDI DRE 210, GORNATI LEGOOR 200 and M.C.M. ATL GIOTTO are a few makes and models of CNC lathe machine in the offering. This machine is employed for performing cutting, drilling, knurling, wood turning and other operations.

Lal Chand Metal & Machines is a reliable provider of gear tester machine of makes and models, like KLINGELNBERG PFSU 1200, MAAG PH 100, CARL MAHR and HURTH - ZP 300. These machines allows the user to quickly and easily measure gears.

It is possible to produce helical gears, spur gears, screws, etc., making use of a versatile machine called gear grinder machine. This machine is apt for fulfilling all requirements, whether you need it for batch production, volume production or prototyping.

Gear Shaper Machine available in models, like LORENZ S5, FELLOWS 4GS and STANKOIMPORT 5M161, can be used in the manufacturing of gears, mainly for internally cut gears. Customers can make the selection easier by going through the specification of every machine.

Gear Hob Sharpener is provided in variety of makes and models, which can be identified by longitudinal travel, grinding diameter, grinding length, helical pitch and other technical specifications. This machine comes with a number of accessories.

Get in touch with us